Detailed Selling Lead Description

Model: XC-113

DESCRIPTION

Crosslinker XC-113 is a 100% active, polyfunctional aziridineliquid crosslinker. Addition of 1-3% to water based acrylic emulsions or urethane dispersions produces a marked improvement in water, chemical, abrasion and humidity resistance and enhances adhesion to specific substrates. Crosslinker XC-113 is room temperature reactive and therefore can be used under air and forced drying conditions.

SPECIFICATION

Type: polyfunctional aziridine crosslinker

Appearance: pale yellowish clear liquid

Total solids (w/w %) > 99

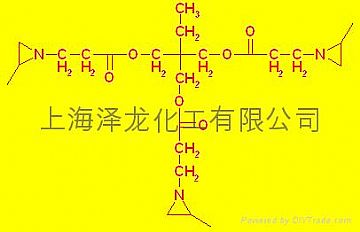

Molecular Formula & Weight: C24H41N3O6, 467.67

CAS No.: 64265-57-2

Viscosity Brookfield (25°C): 180-220 mPa.s

pH (25°C): 8-10.5

Density (20°C): 1.08 kg/l

Stability (20°C): 12-18 months

Flash Point (TCC): >100°C

Freezing Point: <-15°C

APPLICATION

In water based parquet lacquers to improve water, alcohol, detergent, chemical and abrasion resistance

In water based industrial wood-, plastic- and metal coatings to increase water, alcohol and block resistance

In vinyl coatings to reduce plasticizer migration and improve stain resistance

In water based concrete sealers to improve abrasion resistance

Generally, to improve adhesion of water based systems to non-polar substrates

In solvent based polymers to increase resistance properties

In water based printing inks to improve water and detergent resistance.

FORMUlATING GUIDELINES

Crosslinker XC-113 is a tri-functional material that crosslinks polymers with reactive carboxyl functionalily

Typical addition levels of XC-113 necessary to fully crosslink acrylic emulsions and urethane dispersions are 2% and 3% respectively (calculated on wet products)

Crosslinker XC-113 should be added to lacquers, paints or inks prior to use and due to its excellent water miscibility it can be stirred in by hand.

The best method of addition is by using a 1:1 premix of XC-113 and water.

In water borne formulations, XC-113 will slowly hydrolyse and blends should therefore be used within 3-5 days after preparation. The hydrolised products have no adverse effects on the emulsions nor on the dried films, and additional crosslinker may be added to restore reactivity

Solvent based systems modified by the addition of XC-113 must be used within 5 days because they tend to thicken and may gel within 2 weeks

HANDLING

Care must be taken to avoid any contact with the skin and eyes. When used in spray applications, particular care must be taken to avoid oral and/or nasal ingestion by wearing a suitable respirator. When handling XC-113 it is desireable to prevent inhalation of vapours by proper ventilation or respirator use.

PACKAGE & STORAGE

Available 5Kgs plastic pails, and 25Kgs steel drums with inner plastic pails. Store in a cool, dry, dark place. If stored under conditions of excessive heat for extended periods the material may discolour, deteriorate and gel.