Detailed Selling Lead Description

Model: XC-125

DESCRIPTION

XC-125 is a type of aziridine terminated isocyanate crosslinker, possesses special note of stable at room-temperature and can crosslink in high temperature (>130 degree), therefore it can be used as a mono-component crosslinker in the basic system of acrylic and polyurethane waterborn resins; Commercial XC-125 product is a water-dispersible liquid used as dying additive for improving bonding strength of various adhesives; XC-125 can be used in various fields when strong bonding effect is required; XC-125 powder is also used in the system of powder resin., this crosslinking agent does not contain formaldehyde.

SPECIFICATION

Appearance: white water-dispersible liquid;

Total Solid (w/w ): NV;

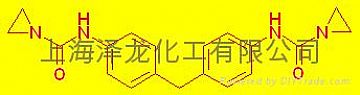

Molecular Formula & Weight: C19H20N4O2, 336.40;

CAS No.: 7417-99-4;

Viscosity, at 25°C: <300cps;

PH at 25°C: 9-10;

Specific Gravity at 25°C: 1.05-1.1g/ml;

Freezing Point (°C) <-5;

Flash Point (°C) (TCC): >100 (water reflux); >130 (decompose).

APPLICATIONAS

In the system water based printed paste, can improve the abrasion resistance and gloss finish, not formaldehyde appear;

In water based acrylic resin and polyurethane latex, increase cohesive strength after heat treatment;

In any water based latex containing –COOH, -OH, -NH2, improves the resin strength and abrasion resistance, after dry and heat treatment;

In water based cotton & terylene latex, increases water and oil resistance;

In vinyl coatings to reduce plasticizer migration and improve stain resistance;

In water based concrete sealers to improve abrasion resistance

Generally, in any water based resins, improve the water, detergent, solvent, chemical resistance and abrasion resistance, after heat treatment formulation.

TYPICAL APPLICATION AS CROSSLINKER

Method of Addition: XC-125 is added slowly and with good agitation, directly to the formulated coating system which the PH value must be controlled between 8-10, avoid to use in acidic medium;

Addition Levels. The level of XC-125 to add to the formulated system will depend on the coating system and the desired properties of the coating film. Most applications find use levels between 1% and 3% based on total resin amount. Higher levels, such as 5%, may yield higher solvent resistance and adhesion properties;

CONTAINER INFORMATION & STORAGE CONDITIONS

Available in 25kg plastic drums and 5kg plastic drums; Store in cool and dry place with adequate ventilation; pot life is about 12-18 months.