Detailed Selling Lead Description

Model: TLY-YG-AB

Product Description

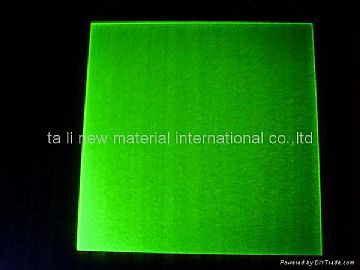

luminescent films are second-generation glow in dark products based on photoluminescent pigments, using our research and technology developed in our company. They are made of flexible thin PVC films. The back of these films can be coated with permanent acrylic adhesive and backed with a polycoated release liner. These products are non-toxic, non-radioactive with high luminescent intensity, durable and easy to use.

Specifications

1. Relative fire resistant .

2. Relative acid / alkaline resistant (can be cleaned with detergents).

3. Good physics and mechanical properties.

4. Weather resistant, can be used in environments between -20-50 degree C.

5. High luminescent intensity, convenient and easy to install.

IV. Directions to Use and Precautionary Statements

1. Use on smooth and flat surfaces with temperature between 10-40 degree C.

2. The films can be cut into various sizes and shapes according to needs and apply directly onto desired objects such as phone, light switches etc.

3. Figures and texts can be printed on photoluminescent films to provide special designs with background luminescence.

4. Apply only to surfaces that are clean, dry, oil and dust free.

5. Photoluminescent films may expand and contract in response to temperature fluctuations. To prevent transformation, unused films should be clipped or placed in between two flat surfaces with weights.

6. Photoluminescent films with back adhesive and release liner are sensitive to humidity. To prevent curling, these films should be processed and used in environments with relative humidity between 40-60%.

7. To install the photoluminescent film, simply peel off the backing liner paper, position it over the treated surface and evenly apply pressure over the entire surface of the films. Make sure that all sides and corners of the films are properly attached to the surface.