Detailed Selling Lead Description

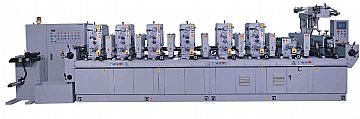

LLR-300 machine’s producing line is following and pasted CE recognizes having very tough control system. It compare with all other world Label printing machine has a lot of surpassing superiority.

Machine easy to operate.

Maintenance is simple.

Less waste paper .

Excellence and precise printing quality.

Second pass printing is precision.

Exchange printing plate time is short and easy.

Computer control.

Friendly Human interface control system.

Auto Oil supply system .

Less machine parts consume.

Stable used for long time operate.

With Link-Label LLR-300 Full rotary/ Intermittent it has considerably space to choose the process product. The process product could make into two different size, one is full rotary with 240mm of printing size and the other one is Intermittent with the size around 50mm~210mm. With Intermittent the different size of printing work do not need to change the printing cylinder with the LLR-300’s computer program it will automatic calculate it’s printing operation and also with different material the printing speed can go up to 200RPM. When the printing size is up till 240mm just need to change the process from Intermittent to Full rotary on the human interface. The full rotary speed can run 50m/min with the process.

LLR-300 can easily doing second pass printing it improve polychrome printing product, we use SICK high quality photoelectric cell its’ scanning is accurate and fairly steadiness, it can also doing back side printing.

LLR-300 use Human control interface let engineer easy to learn with, engineer just need to set in the working way, and the printing size with the printing speed and the data into the computer program, than it will run automatically. When there is wrong operate progress or un-normal manipulate the Human control interface will send the message to the new operator make the new learner can learn faster.

Link-Label designs the plate cylinder focusing on ergonomics, so we make removable plate cylinder. The processor can remove the cylinder put in to LLR-300’s plate sitting unit to change the plate using the double side stickiness material.